As the ecological problems caused by global temperature changes become more and more obvious, glaciers melt, sea levels rise, flooding coastal countries and lowland areas, extreme weather continues to appear...These are problems all caused by excessive carbon emissions, and carbon reduction actions are imperative. To solve the problem of carbon emissions, it is necessary to accelerate the large-scale development and widespread use of clean energy.Solar energy is considered to be one of the best renewable energy sources, and with the continuous development of science and technology, solar energy is more and more widely used.

The following is the CCIC quality inspection method for solar lamps:

1. Product inspection sampling plan

ISO2859/BS6001/MIL-STD-105E/ANSI/ASQC Z1.4

2. Solar lamp appearance and workmanship checking

The appearance and workmanship inspection of solar lamps is the same as other types of lamps, including styles, materials, colors, packaging, logos, labels, etc.

3. Special test for solar lights quality inspection

a. Transportation carton drop test

To carry out the carton drop test as per ISTA 1A standard. After drops, the solar lamp product and packaging should have no fatal or serious problems.

b. Product size and weight measurement

According to the solar lamp specification and approved sample, if the customer does not provide detailed tolerances or tolerance requirements, a tolerance of +/-3% is acceptable.

c. Barcode verification test

the barcode of the solar lamp can be scanned, and the scanning result is correct.

d. Full assembly check

According to the manual, the solar lamp can be assembled normally.

d. Complex function check

The samples shall be powered with rated voltage and work for at least 4 hours under full load or according to the instruction (if less than 4 hours). After the test, the solar lamp sample shall be able to pass the high voltage test, function test, grounding resistance test, etc., and there shall be no defects in the junction test.

e. Input power measurement

The power consumption/input power/current of the solar lamp should conform to the product specifications and safety standards

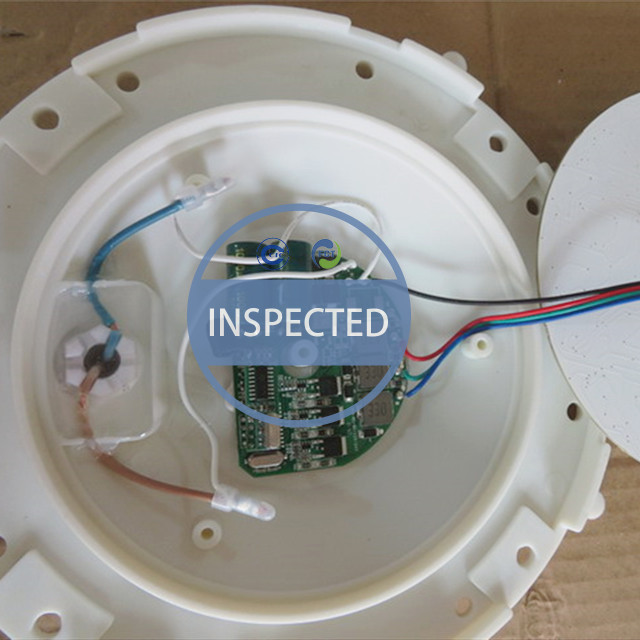

f. Internal work and inspection of key components: inspection of the internal structure and components of the solar lamp, the line should not touch the edge, heating parts, moving parts to avoid insulation damage. Solar lamp internal connection should be fixed, CDF or CCL elements should meet the requirements.

g. Critical component and internal check

Inspection of the internal structure and components of the solar lamp, the line should not touch the edge, heating parts, moving parts to avoid insulation damage. Solar lamp internal connection should be fixed, CDF or CCL elements should meet the requirements.

h. Charge and discharge inspection (solar cell, rechargeable battery)

Charge and discharge according to the stated requirements, should meet the requirements.

i. Waterproof test

IP55/68 waterproof, water spraying solar lamp after two hours will not affect the function.

j. Battery voltage test

Rated voltage 1.2v.

If you have any interested,please contact us at any time.

CCIC inspection company could your eyes,we will help you to check the product quality and let you get the high quality products at the lowest cost.

Post time: Nov-29-2022