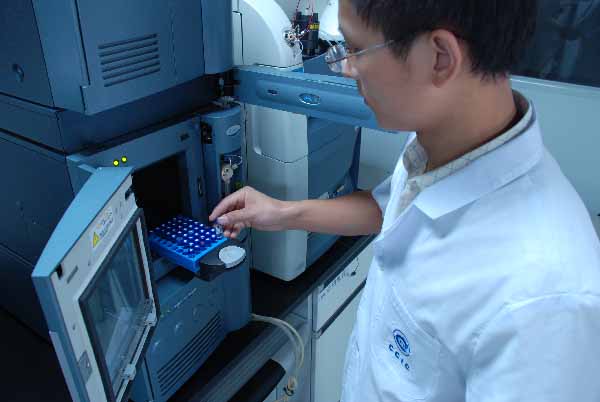

Manufacturer of Scc Training - During Production Inspection – CCIC

Manufacturer of Scc Training - During Production Inspection – CCIC Detail:

A visual check on the quality of components, materials, semi-finished and finished products when at least 10%-20% of the order has been completed. The production batch and those products in the line would be randomly inspected for possible defect. If any problem occurs, identifies the deviation and provides advice on the corrective measures that are necessary to ensure a uniform batch quality and a quality product.

- Inspection I normally done as the product is through the finishing process. That means inspection shall be conducted when 10%-20% of goods are finished checking or packed into the polybag;

- It shall find out defects in the earliest stages;

- Record the size or color, which will not be available for inspection.

- Check semi-finished goods on every production processes. (production status);

- Proportionally and randomly check the goods during the inspection (Level 2 or otherwise specified by applicant);

- Mainly search the cause of defect and suggest corrective action plan;

- No AQL will be applied;

- Many need several DPI to ensure continuous improvement before FRI upon applicant’s request.

Product detail pictures:

Related Product Guide:

Manufacturing flexible printed circuit boards without any chemicals | Tested Quality

Streaming fashion in Cuba | Business| Economy and finance news from a German perspective | DW | Deteriorate Deutsch

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for Manufacturer of Scc Training - During Production Inspection – CCIC , The product will supply to all over the world, such as: Croatia , Rio de Janeiro , Canada , We offer OEM services and replacement parts to meet the varying needs of our customers. We offer competitive price for quality products and we will make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

CCIC-FCT thirty party inspection company,provide inspection service to global buyers.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.

Write your message here and send it to us