OEM/ODM Manufacturer Product Inspections - During Production Inspection – CCIC

OEM/ODM Manufacturer Product Inspections - During Production Inspection – CCIC Detail:

A visual check on the quality of components, materials, semi-finished and finished products when at least 10%-20% of the order has been completed. The production batch and those products in the line would be randomly inspected for possible defect. If any problem occurs, identifies the deviation and provides advice on the corrective measures that are necessary to ensure a uniform batch quality and a quality product.

- Inspection I normally done as the product is through the finishing process. That means inspection shall be conducted when 10%-20% of goods are finished checking or packed into the polybag;

- It shall find out defects in the earliest stages;

- Record the size or color, which will not be available for inspection.

- Check semi-finished goods on every production processes. (production status);

- Proportionally and randomly check the goods during the inspection (Level 2 or otherwise specified by applicant);

- Mainly search the cause of defect and suggest corrective action plan;

- No AQL will be applied;

- Many need several DPI to ensure continuous improvement before FRI upon applicant’s request.

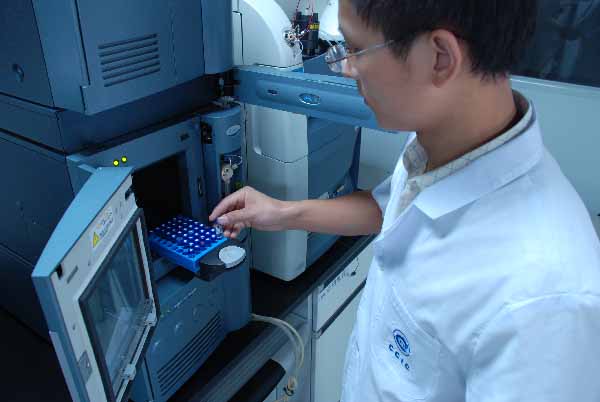

Product detail pictures:

Related Product Guide:

Smoking, high blood pressure, diabetes and obesity each linked to unhealthy brains | Production Quality

Telehealth: Two Steps Forward For Payment, Three Steps Back For Fraud? | Akerman LLP | Production Quality

High quality Initial,and Buyer Supreme is our guideline to offer the ideal assistance to our shoppers.At present, we are striving our best to become amongst the ideal exporters inside our industry to satisfy shoppers more want for OEM/ODM Manufacturer Product Inspections - During Production Inspection – CCIC , The product will supply to all over the world, such as: Sevilla , Zimbabwe , Orlando , As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to provide our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

CCIC-FCT thirty party inspection company,provide inspection service to global buyers.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.

Write your message here and send it to us