Wood products refer to products formed by processing wood as raw materials.Wooden products are closely related to our life, such as the sofa in the living room, the bed in the room, the chopsticks we usually use for eating, etc. Its quality and safety are concerned, and the inspection and testing of wood products are particularly important.In recent years, Chinese wooden products, such as racks, cutting boards, tables, etc., are also very popular in overseas markets such as Amazon's e-commerce platform.So how to inspect wood products? What are the standards and main defects of wood products inspection?

Quality Inspection standards and requirements for wooden furniture

a.Appearance check

Smooth surface, no unevenness, no spikes,free of damaged,scratch,crackle etc.

b.Product size, weight est

According to the product specification or the sample provided by the customer, measuring the product size, thickness, weight, outer box size, outer box gross weight. If the customer does not provide detailed tolerance requirements, +/-3% tolerance should be used in general.

c.Static load test

Many furniture needs to be static load tested before shipment, such as tables, chairs, reclining chairs, racks, etc. Load a certain weight on the load-bearing parts of the tested product, such as chair seat, backrest, armrest, etc. The product should not be overturned, dumped, cracked, deformed, etc. After the test, it will not affect the functional use.

d.Stability test

The load-bearing parts of wooden furniture also need to be tested for stability during inspection. After the sample is assembled, use a certain force to pull the product horizontally to observe whether it is overturned; place it horizontally on the flat plate, and do not allow the base to swing.

e.odor test

The finished product should be free of unpleasant or pungent odors.

f.Barcode scanning test

Product labels,FBA labels can be scanned by barcode scanners and the scan results are correct.

g.Impact test

A load of a certain weight and size that falls freely onto the furniture bearing surface at a specified height. After the test, the base is not allowed to have cracks or deformation, which will not affect the use.

h.Humidity test

Use a standard moisture tester to check the moisture content of wooden parts.

When the moisture content of wood changes greatly, uneven internal stress occurs inside the wood, and major defects such as deformation, warpage, and cracking occur in the appearance of the wood. Generally, the moisture content of solid wood in Jiangsu and Zhejiang areas is controlled according to the following standards: the solid wood material preparation section is controlled between 6% and 8%, the machining section and assembly section are controlled between 8% and 10%, the moisture content of the three plywood is controlled between 6% and 12%, and the multi-layer Plywood, particleboard, and medium density fiberboard are controlled between 6% and 10%. The humidity of general products should be controlled below 12%.

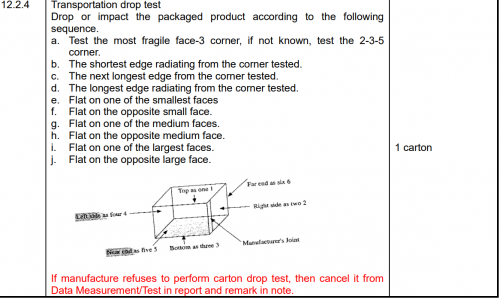

i.Transpotation drop test

Perform drop test according to ISTA 1A standard, according to the principle of one point, three sides and six sides, drop the product from a certain height for 10 times, and the product and packaging should be free of fatal and serious problems. This test is mainly used to simulate the free fall that the product may be subjected to during handling, and to examine the ability of the product to resist accidental shocks.

The above is the inspection method of wood products, hope it useful to everyone. If you have other questions, you can contact us.

CCIC FCT as a professional inspection team, every our inspector in our team has more than three years of inspection experience, and pass our regular assessment. CCIC-FCT could be your always product quality control consultant.

Post time: Sep-27-2022